The Importance of the Winding Process

The winding process is an indispensable process in the spinning process. With the development of the semi-worsted spinning process, the role of the automatic winder in the semi-worsted spinning production has been paid more and more attention. In semi-worsted spinning production, more advanced automatic winders are generally used, mostly equipped with electronic yarn clearers and air splicers, with high automation, low failure rate and high winding quality. The biggest advantage is variety adaptability powerful. Moreover, for some special semi-worsted yarn varieties, it may not be able to be produced normally on ordinary winders, but using automatic winders can achieve twice the result with half the effort.

Therefore, in view of the particularity of the semi-worsted yarn and the production difficulties of the winding process, how to make good use of the automatic winder in the practice of semi-worsted spinning is a new subject.

Characteristics of semi-worsted yarns

"Semi-worsted" products are between worsted and coarse wool. At present, most of the "semi-worsted spinning" in the industry are organically combined with wool spinning equipment and cotton spinning equipment, integrating cotton spinning technology with wool spinning technology. Compared with worsted spinning, the production process is shorter, forming a new type of spinning process. . The yarn has the characteristics of good evenness and cleanliness of combed yarn, and has the characteristics of good hand, good elasticity and fluffy of carded yarn, and has a wide range of spun counts and strong applicability of raw materials. Compared with the carded yarn, the evenness CV value is reduced, and the anti-pilling index is also improved.

After several years of development, the semi-worsted spinning technology has begun to take shape in the industry. Now its products are not only wool yarns, but also the production of cotton, silk, hemp and other blended dyed yarns, and have penetrated into cotton spinning, silk spinning and other industries. Semi-worsted yarn has the following characteristics: variety of varieties, mixed raw materials; yarn twist is generally larger than that of cotton yarn and worsted wool yarn of the same size, and some products are strongly twisted yarn, which makes it difficult to untwist when twisting; After dyeing, the strength of single fiber is damaged to varying degrees, especially for cotton, wool and cashmere products, short piles will be produced during carding, resulting in many frequent yarn defects and high shear rate of electric clearing. , there are many joints, so the requirements for knots are higher; some special semi-worsted yarns have particularly low single yarn strength, which has a great influence on the quality of knots and the initial tension and initial speed of winding; high-grade yarns , the customer has high requirements for the appearance and defects of the yarn, and the requirements for the strength and appearance of the knot are also higher.

In view of the above characteristics, the use of automatic winding machines to produce semi-worsted yarns is likely to cause poor twisting and inherent quality problems in the bobbin. As far as the semi-worsted yarns of high grade and high price are concerned, the control of the yarn return rate of the automatic winder cannot be ignored.

ZHEJIANG KAICHENG INTELLIGENT MACHINERY CO.,LTD not only has Automatic High-speed Precision Winder Manufacture but also Air Texturing Machine Manufacture, welcome to visit our official website.

hot Products

-

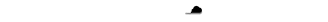

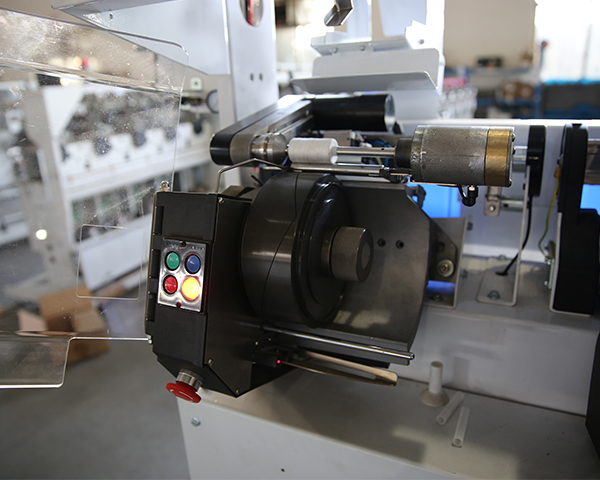

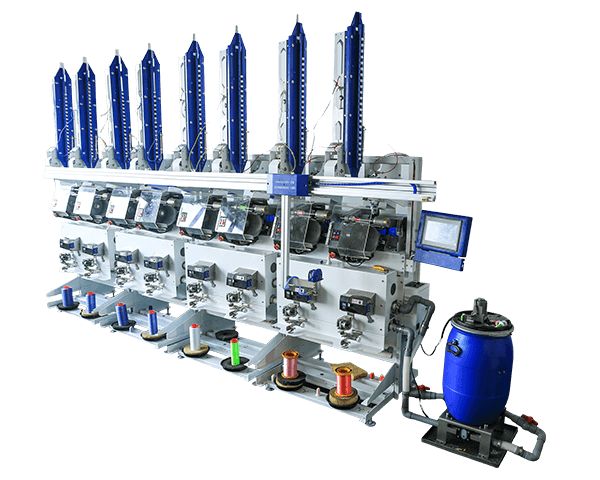

KC212 Intelligent electronic yarn precison winder

-

KC215B Electronic yarn guide air covering machine

-

KC215C Air texturing machine

-

KC228 High speed precision skeining machine

-

KC522A Automatic high-speed winder

-

KC522B Automatic high-speed winder

-

KC522C Automatic high-speed winder

-

KC522D Automatic high-speed winder

-

KC522E Automatic high-speed winder

-

KC522F Automatic high-speed winder