The Working Principle and Application of Winder Accessories

The winder has a special purpose in the textile industry. It is the link connecting the two processes of spinning and weaving, so it has an important position in the textile industry. Once there is a problem with the winder accessories, the entire textile process will be completely destroyed and irreparable. This will not only damage the spinning of the upper process, but also make the weaving of the downstream process unable to operate normally. Therefore, the quality of the winder is self-evident for the entire textile process.

1. Main tasks

The main tasks of the winding machine accessories are: 1. Connect the cops with less capacity through the winding to make a bobbin with a larger capacity, thereby increasing the yarn capacity of the yarn package. The yarn device cleans the yarn defects and sundries, improves the quality of the yarn, and provides convenience for the subsequent process.

2. Process requirements

The technological requirements for the accessories of the winder are very strict, and no wire climbing can be produced during the traversing process. If it occurs, it will affect the unwinding process. Hard edges should not appear during the winding process to prevent affecting the dyeing process. The yarns should not overlap, otherwise the yarn friction will be aggravated, resulting in the vibration of the winding.

Winder accessories need to be effectively controlled in the process of use, and implemented in strict accordance with the production process. As a special equipment, the winder is the most basic requirement of the process to ensure its normal operation, and it is also the basis for the realization of the entire textile process.

ZHEJIANG KAICHENG INTELLIGENT MACHINERY CO.,LTD not only has Automatic High-speed Precision Winder Manufacture but also Air Texturing Machine Manufacture, etc. Welcome to our official website.

hot Products

-

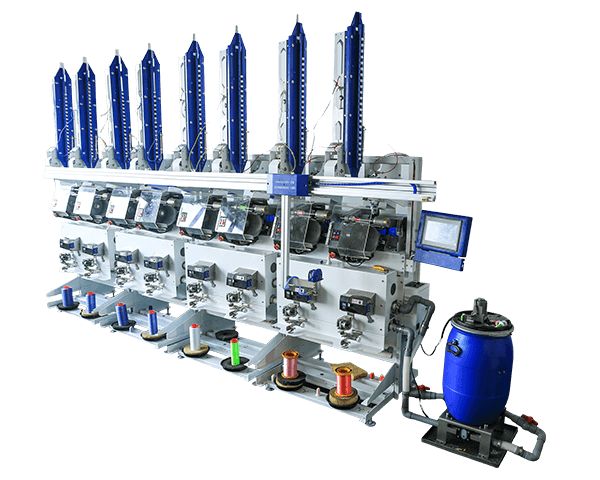

KC212 Intelligent electronic yarn precison winder

-

KC215B Electronic yarn guide air covering machine

-

KC215C Air texturing machine

-

KC228 High speed precision skeining machine

-

KC522A Automatic high-speed winder

-

KC522B Automatic high-speed winder

-

KC522C Automatic high-speed winder

-

KC522D Automatic high-speed winder

-

KC522E Automatic high-speed winder

-

KC522F Automatic high-speed winder