Main Tasks of Precision Winder

1. Change the package and increase the yarn capacity of the yarn package:

Connect the tube yarn (or skein yarn) with less capacity through winding to make a package with larger capacity. The capacity of one package is equivalent to more than 20 tube yarns. The package can be used for warping, twisting, weft winding, dyeing, weft on shuttleless looms and knitting yarn.

If tube yarn is directly used in these processes, it will cause too much downtime, affect the improvement of production efficiency, and also affect the improvement of product quality. Therefore, increasing the package capacity is a necessary condition to improve the productivity and quality of the next process.

2. Remove the defects on the yarn and improve the yarn quality:

There are some defects and impurities in the yarn produced by the cotton mill, such as slubs, details, double yarn, weak twist yarn, neps, etc. During winding, yarn cleaning device is used to check the yarn, remove the defects and impurities on the yarn that affect the quality of the fabric, improve the evenness and smoothness of the yarn, so as to reduce yarn breakage in the next process and improve the appearance quality of the fabric. It is most reasonable for the defects and impurities on the yarn to be removed in the winding process, because the work of each package is carried out independently during winding. When a package is broken, other packages can continue to work without being affected.

ZHEJIANG KAICHENG INTELLIGENT MACHINERY CO., LTD. has not only Automatic High speed Precision Winder Manufacture, but also Air Covering Machine and other products. Welcome to visit our official website.

hot Products

-

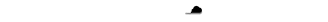

KC212 Intelligent electronic yarn precison winder

-

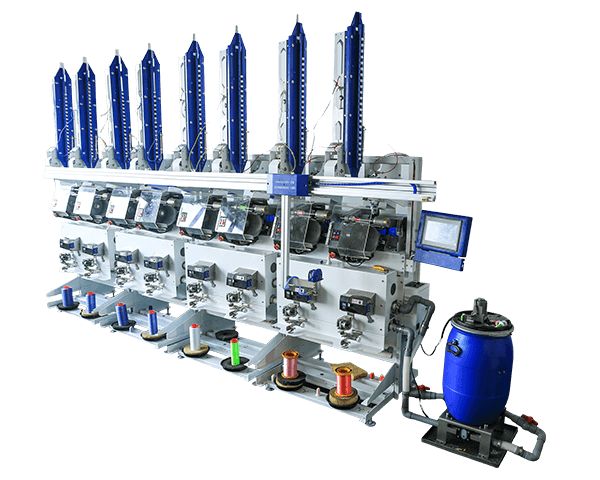

KC215B Electronic yarn guide air covering machine

-

KC215C Air texturing machine

-

KC228 High speed precision skeining machine

-

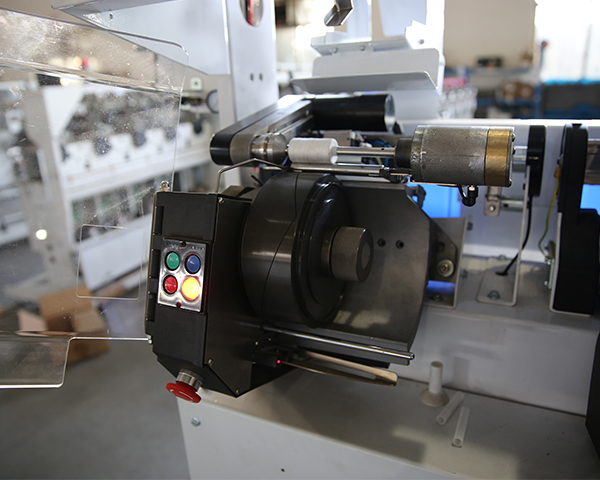

KC522A Automatic high-speed winder

-

KC522B Automatic high-speed winder

-

KC522C Automatic high-speed winder

-

KC522D Automatic high-speed winder

-

KC522E Automatic high-speed winder

-

KC522F Automatic high-speed winder