Differences Between Different Types of Twisting Machines

Twisting machine is a kind of textile mechanical equipment that twists multiple strands of yarn into one strand. The twisting machine is used to process the yarn or folded yarn products into linear products for weaving and knitting. The utility model comprises a twisting machine body and a circuit part. The spindle outside the twisting machine body is connected to the motor output shaft of the circuit part. The front end of the spindle is provided with a connector that corresponds to the tap changer.

Double twister

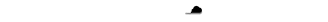

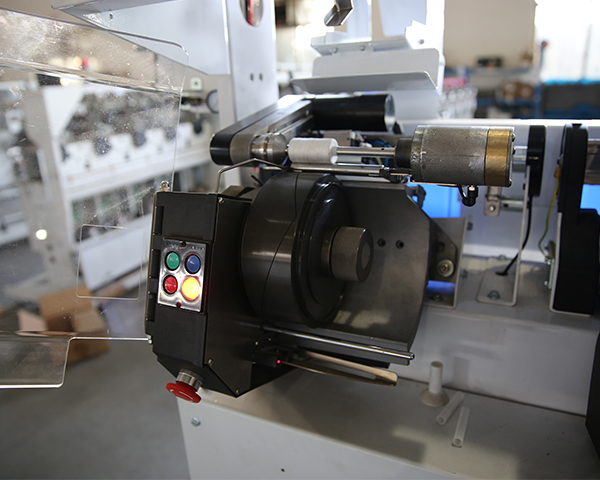

With a double-twist spindle as the main twisting machine, each rotation can add two twists to the plied yarn. There are three types of double-twist spindles: vertical spindle, horizontal spindle and inclined spindle, most of which are vertical spindles. The utility model is composed of a spindle, a spindle disk, a yarn storage disk and other rotating parts, and a yarn holding tank, a hollow spindle tube and other fixed parts. The fixed part is sleeved outside the rotary part and connected with the rolling bearing. The spindle plate is driven by a dragon belt or spindle belt to drive the yarn storage plate to rotate together. In order to ensure that the fixed part is not affected by the rotary part, the brake device of the yarn container is generally installed. There are three braking modes: magnetic braking, gravity braking and mechanical braking. The plied yarn is drawn from the supply bobbin, threaded through the top of the hollow spindle tube, threaded through the side hole of the yarn storage tray, and wound onto the bobbin through the yarn guide hook and the output roller. When the spindle or yarn storage disk rotates for one circle, add one twist back to the yarn in the hollow spindle tube and the balloon part between the side hole of the yarn storage disk and the yarn guide hook. When the direction is the same, two twists are obtained. The spindle speed of this twister is up to 14000 rpm, and the twisting efficiency is doubled. It can be directly made into packages with large capacities. The doffing times are reduced, but the power consumption is large, and the joint operation is difficult.

Ring twister

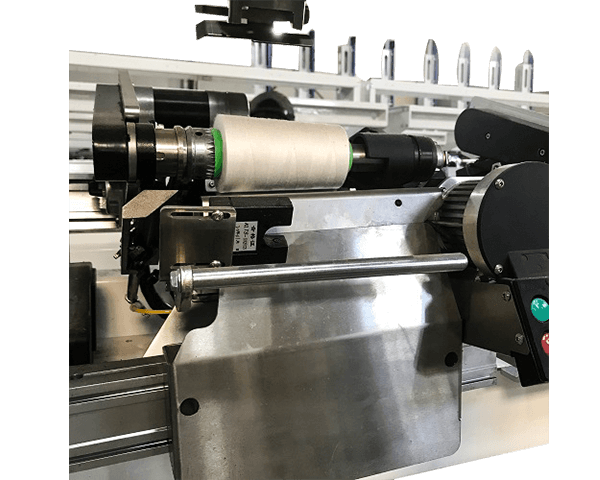

The plied yarn drawn from the bobbin is output from the yarn guide roller through the yarn guide rod and the traverse yarn guide and is wound on the bobbin through the yarn guide hook and the steel wire ring. When the spindle drives the bobbin to rotate together, the yarn drives the steel ring to rotate on the annular ring to twist the yarn.

Most of the bobbins on the bobbin frame are looped on the inserting spindle in a horizontal way, and the plied yarn pulls the bobbin to rotate from the side and unwinds. The combined twisting machine is fed with a single yarn package. In order to reduce the end breakage caused by excessive tension during single yarn unwinding, a cone-shaped package is tightly sleeved on the insertion spindle, and the single yarn is axially led out from the respective package ends. The feeding frame is used for merging. The doubling and twisting machine can save the doubling process and is generally only suitable for spinning double-ply yarn with low-quality requirements. The guide roller is usually a pair of smooth round rollers. The lower roller is a 6-8 ingot section, which is spliced with its full length. Each spindle of the upper roller is pressurized by its own weight and driven by the friction of the lower roller. There is a certain threading method for the plied yarn on the roller so that there is a long enough friction surrounding the arc between the yarn and the roller to ensure that the roller conveys the yarn to the twisting area at a uniform speed. Some of them use two lower rollers, or even two pairs of rollers, on the specially spun thick-ply yarn or a multi-twist twisting machine to adapt to the high twisting tension and achieve the goal of uniform yarn feeding. In the roller part, some twisting machines are equipped with a self-stop device for breaking ends. Some twisters are called wet twisters because there is a water tank under the yarn guide rod, and the plied yarn is wetted before twisting. The wet twisted yarn has the advantages of high strength and smooth surface, but the roller and yarn guide parts need to use rust-proof materials.

ZHEJIANG KAICHENG INTELLIGENT MACHINERY CO.,LTD not only has Twisting Machine but also Filament Yarn Twister and other products, welcome to visit our official website.

hot Products

-

KC212 Intelligent electronic yarn precison winder

-

KC215B Electronic yarn guide air covering machine

-

KC215C Air texturing machine

-

KC228 High speed precision skeining machine

-

KC522A Automatic high-speed winder

-

KC522B Automatic high-speed winder

-

KC522C Automatic high-speed winder

-

KC522D Automatic high-speed winder

-

KC522E Automatic high-speed winder

-

KC522F Automatic high-speed winder