How Twisting Machine Work

What is a twisting machine?

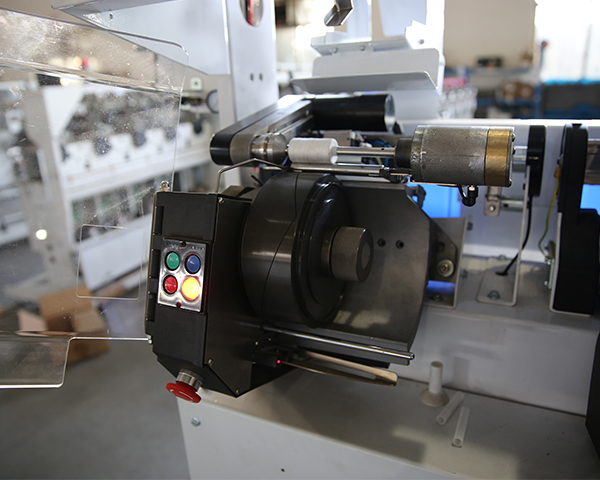

A machine resembling a ring spinning-frame, for twisting two or more threads or yarns, like cotton, together with by the rotation of a spindle or a similar device.

Twisting machine operators tend machines that spin two or more fibers together into yarn. They handle raw materials, prepare them for processing, and use twisting machines for the purpose. They also perform routine maintenance of the machinery.

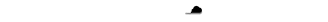

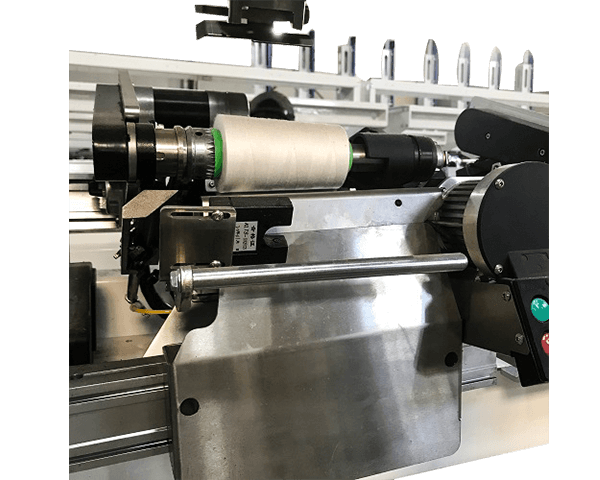

Twisting machine in textile machinery that twists multiple strands of yarn into one strand. The function is to process yarn or merged stranded yarn products into linear products for weaving and knitting. The spindle outside the twister body is connected with the motor output shaft of the circuit part, and the front end of the spindle is equipped with connectors, which correspond to the tap-changer.

The working principle of twisting machine:

the plied yarn is drawn from the cylinder, through the guide rod and the transverse guide device, from the guide roller output, through the guide hook and travelling coil around the tube. When the spindle drives the tube to rotate together, the yarn pulls the traveller to rotate on the ring ring ring and twists the yarn.

That's how the twister works. Twister is mainly used in twisting and plying engineering of cotton yarn, chemical fibre, silk and glass fibre.

hot Products

-

KC212 Intelligent electronic yarn precison winder

-

KC215B Electronic yarn guide air covering machine

-

KC215C Air texturing machine

-

KC228 High speed precision skeining machine

-

KC522A Automatic high-speed winder

-

KC522B Automatic high-speed winder

-

KC522C Automatic high-speed winder

-

KC522D Automatic high-speed winder

-

KC522E Automatic high-speed winder

-

KC522F Automatic high-speed winder